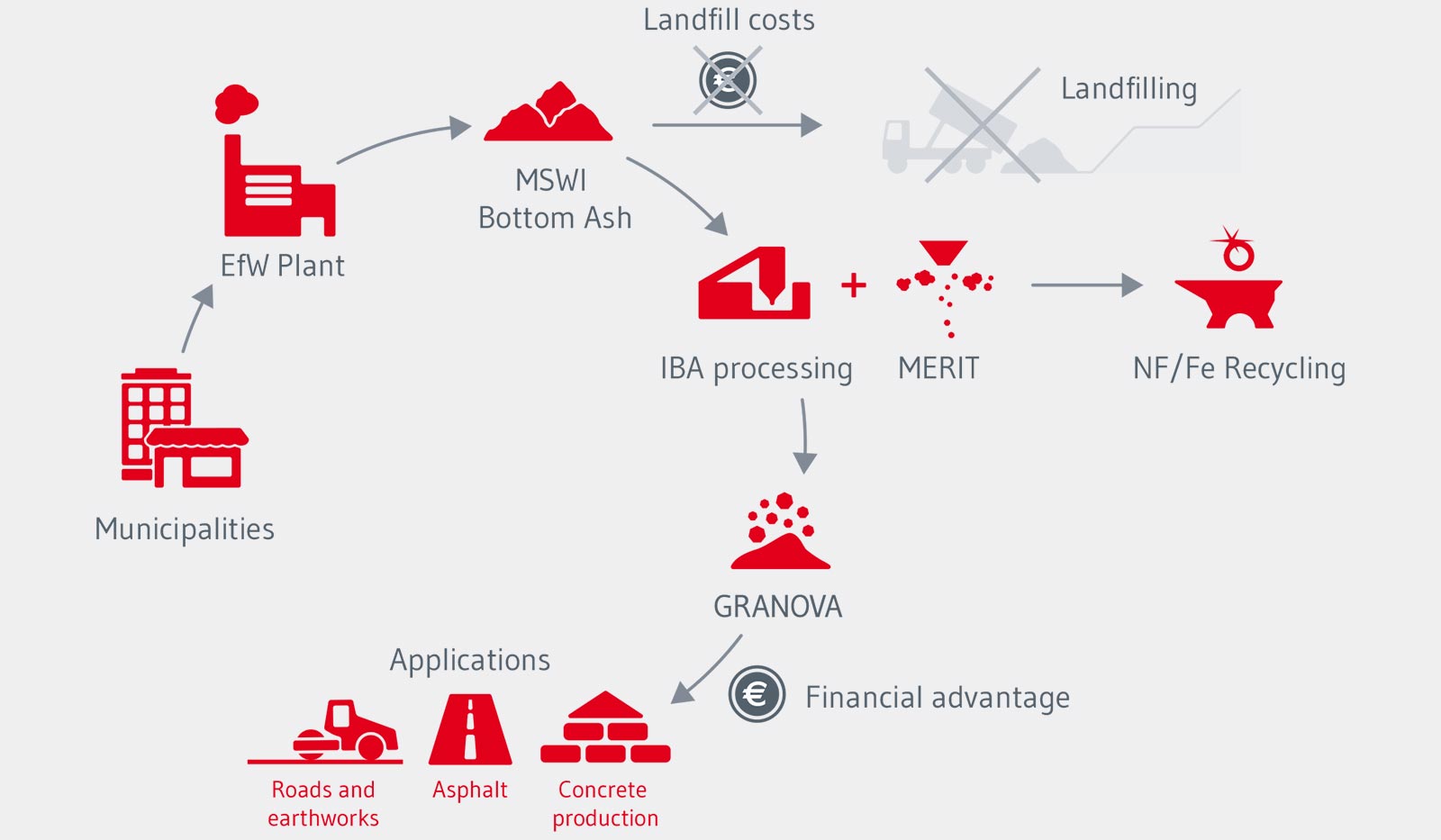

GRANOVA is unique

GRANOVA differs from other IBAA because of its quality. We were the first producers of IBAA holding the KOMO® certification for use as aggregate in concrete. To achieve this level of application, we are committed to improving the metal extraction rates and mineral quality. Our efforts are supported by our internal and external research initiatives. The results of these are demonstrated in our significant annual investments in plant technology. We are proud of our determination to ascertain better ways of using waste. This effort is rewarded by the market: we are the only mineral recycling brand serving customers across several EU countries as well as in Asia.